Expecting a long-lasting and high-quality printing? Sublimation Printing is a one method known for its perfection. If you want to know “What is sublimation printing and how to go about it?”, you are at the right place.

This blog is all about guiding you on how to use sublimation printing on products.

What is Sublimation Printing?

Going with the basics, first it is important to understand the method, its purpose, use cases etc.

The word sublimation means changing the material from a solid form into a gas without passing through the liquid stage.

The same way, print vendors transfer ink in a solid state to the substrate under a high temperature and pressure. The ink thus changes into its gaseous state on the substrate and bypasses the liquid stage. This leaves no inks to dry on the substrate (object to print on). There are hardly any chances of distortions that would otherwise show up during the drying phase. The design, thus, remains more stable and permanent.

In the sublimation printing process, you infuse the image first onto the sublimation paper. From sublimation paper, you transfer the image to the substrate. The entire process is mess-free, easy, and speedy.

Equipment Required for Sublimation Printing Process

1. Sublimation Printer

A sublimation printer is the first and foremost requirement for sublimation printing. There are various types of sublimation printers available out there. You can pick a variant as per your requirements and scale of production. Earlier, sublimation printers used to be expensive. Now that the demand has increased, prices dropped of late. To get help choose the right variant, you can refer to our previous blog.

2. Sublimation Paper

With a sublimation printer, you can create and transfer any spectrum color onto the substrate. To ensure that transfer is clean and smooth, a sublimation printer is necessary. People also refer to it as a transfer paper. You can print a personal artwork, a custom logo, a picture, or any other such design on the substrate using the sublimation paper.

3. Computer and RIP Software

Some sublimation printers feature software that you need to set up the artwork to print out. These computer programs are RIP software where RIP stands for “Raster Image Processor”. Not every sublimation printer comes with built-in RIP software but you can purchase RIP separately. One thing worth noting here is that the software you pick should be compatible with your type of printing.

4. Cutting Mechanism

You may also need a cutting device for the sublimation printing process. It can be a rotary blade or knife. Some other cutting devices have more than one option to suit all your cutting requirements. For instance, if you want to hem the material, you may need a sewing machine. It is specifically important when you create SEG (Silicone Edge Graphic) frames. So, pick a right cutting device.

5. Heat Press

Another valuable item for sublimation printing is a heat press. This is for the next step in the sublimation printing process after printing. Just like the printer, sublimation transfers also vary in sizes, prices, and models to cater to your exact needs.

A heat press removes the design from the sublimation paper onto the substrate. It can be anything – a coffee mug, t-shirt, tablecloth, etc. With this transfer, it leads to creation of a custom product with a more vivid image resistant to fading. This makes it more durable and long-lasting.

Talking of the dye sublimation printing process, four types of sublimation transfers exist.

Calendar Heat Press

When you use sublimation printing for larger but softer materials, say for fabric signs; a calendar heat press would be an ideal choice. This press is large and can accommodate printing on clothes and banners both.

Small Heat Press

For sublimation printing on small-size items, for example printing a design on hand-held kitchenware, a small heat press can be a better choice. This press is compact, takes less space, and can support pressing on various types of items.

Flatbed Heat Press

To use sublimation printing processes on hard materials like floor tiles or similar home decor items; a flatbed heat press would be recommendable. This press is versatile and helps printing on apparel items.

3D Vacuum Heat Press

To apply sublimation printing for smaller objects varying in shapes and edges, a 3D vacuum heat press is a go-to option. This heat press is suitable for sublimation printing of surfaces that are not flat. It thus opens the field of printing to a much larger range of items.

The USP

There’s one more addition you can make to the list of equipment for the sublimation printing process is online product design software. Want to know how?

If you have an online storefront to take orders from customers, you can go for selling standard items. However, you must understand that offering customization has become a necessity today.

Customization freedom helps in various ways. Businesses can use it for brand awareness promotion. Government organizations can use it to spread awareness about common issues.

Similarly, individuals can use it to send out a message through custom t-shirts, hats, or anything else.

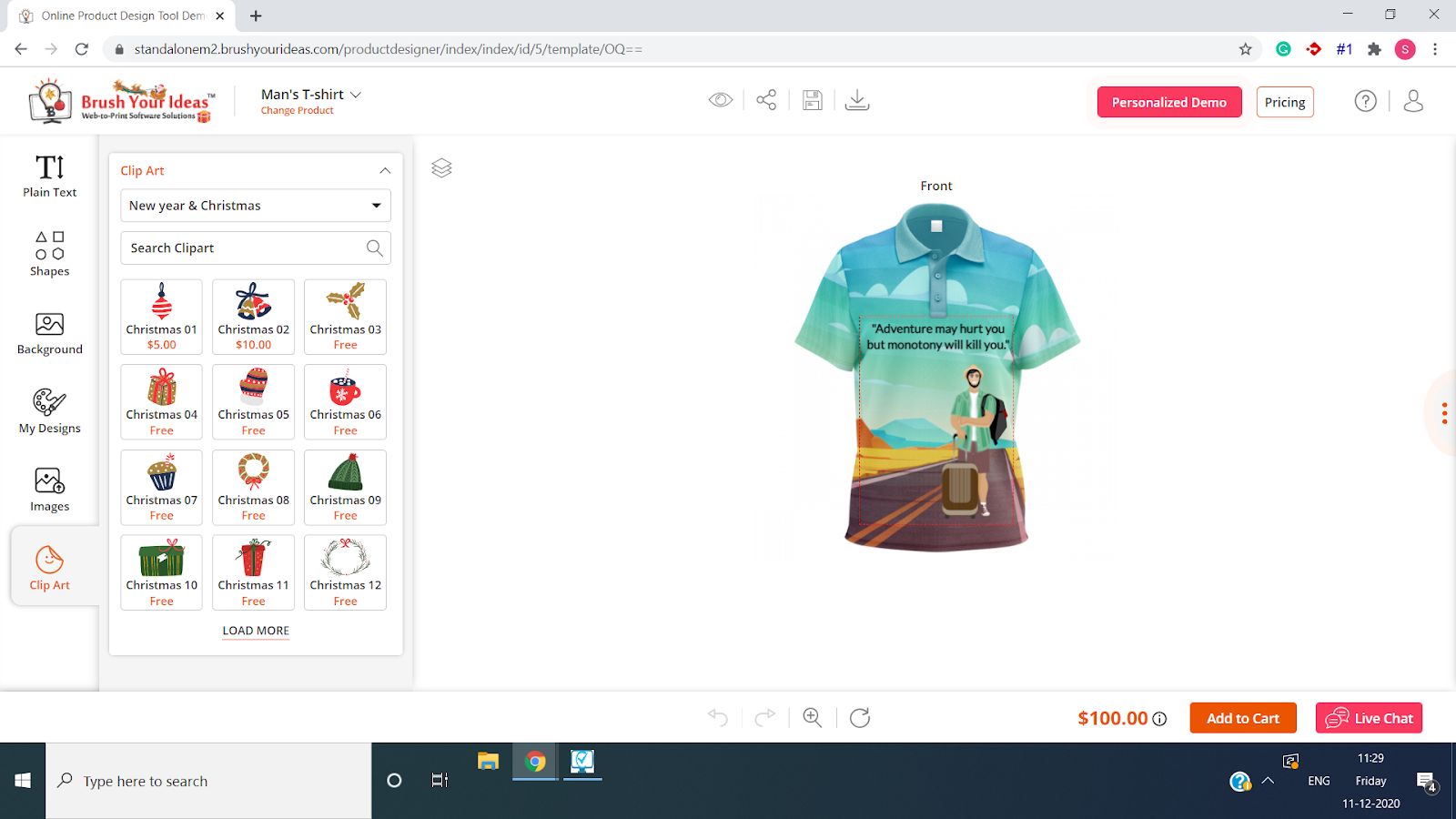

If you wish to allow customers to create custom designs, you should have a means for that. And nothing can be a better option than an online product design tool. By integrating an online product designer with your store, you can offer a wide range of customization options. By offering personalization freedom, you can engage customers and drive high sales.

There is a wide range of options of online product designers available in the market. If you are also looking for an online design tool for your e-store, you can check out our online product designer.

Salient features that make it worth considering are:

Text Features that include custom font manager, name and number, quotes, customizable text and messages.

Image Features that include image edits and effects, personal image upload, design watermarking, image resolution warnings, etc.

Clipart Library that includes clipart library, clipart customization, smart search, SVG support, etc.

Object Handling Features that include object handlers, clear objects, layer management, and object grouping and positioning, etc.

Products You Can Print on with Sublimation Printing

Here is the list of the products you can sublimate on.

- Rigid Substrates – Polymer objects including non-fabric items like fibreglass, aluminum, plastic, glass. You can’t bend these products like fabrics.

- Blank Rigid Items – You can buy several printable items in bulk at wholesale prices. Some examples are mouse pads, phone cases, drinkware, etc. People sometimes call them “blanks”. This is because they have no design or print on them making them a perfect fit for sublimation printing.

- Signages – You can print easily retractable banners, signages, and posters with sublimation printing. Various businesses can order sublimated signages for trade expos, shows, or displays. Vinyl-painted posters and banners are easy-to-locate outside shops and bars.

-

Polyester Fabrics – There are two types of polyester fabrics you can use sublimation printing on.

– Knit polyester items that hang in air such as bags, flyers, flags, table covers, etc.

– Woven polyester items that are more durable and heavy like custom tents and fabric backdrop.

- Home Decor Items for interior designers such as ceramic floor tiles for kitchen, bathroom, or living room.

- Photography Printing – Sublimation printing produces best-quality photographic prints on magnets, canvas, apparels, etc.

Sublimation Printing Process for Different Materials

Sublimation Printing on Fabric

There are various points to consider while applying sublimation printing on fabrics as T-shirts, dresses, custom tents, tablecloths, etc. An “All-over” design is an easy-to-do and popular option where an image or pattern covers the complete print area available.

There are some obstacles though while printing on fabric. Random white creases can creep in on the printed fabric. This can happen if you fail to set the transfer paper properly which causes it to fold over or become wet. Therefore, there is a need to be attentive while setting up prints.

If you want your graphic to be slightly textured, sublimation printing might not be the right choice. It is because you can replicate the look but not the feel using sublimation printing. So, always use your best judgement before you pick a design.

Sublimation Printing on Glass

As glass is a more delicate material, you may need to exercise extra caution when using sublimation printing on glass. You should use the heat press more cautiously. The heat press can also come with an extra covering for the glass, but it isn’t always necessary.

Another thing to understand here is that glass heats up differently from other conventional fabrics that you use. Sometimes, the heat can lead to buil-up of foggy sections in the print. To cover up this issue, using halftones can help. One more solution to it is the use of textured material that gives the impression of a clearer image.

In this approach, there is one thing unique. You should sublimate the ink in the right-reading style as print transfers to the back of the glass and people view it from the other side. In the other materials, you need to sublimate the image in a mirror-image format.

Sublimation Printing on Vinyl

The vinyl sublimation printing process is mostly similar to that for other materials. One major difference is that you use vinyl sublimation for the products fit to cut in shapes.

This method is more useful in products using sticky adhesive. Examples are wall or floor decals. In the vinyl sublimation printing process, you cut the silhouette of the image you need on the design file. After that, you can use the sublimation printer to print it.

At the time of sublimation, cut the vinyl into a proper shape. Cut it close to the edges of the print. You can print over one vinyl product together and cut them separately.

Sublimation Printing on Plastic

Sublimation printing process for plastic materials may need a bit different technology. While a flatbed press may be good for flat surfaces like fabrics, it won’t suit 3-D objects. Instead, a 3-D heat press or oven press may be a more ideal option for printing on 3-D objects.

There is another difference too. You’ll need to print the image on the film instead of paper for its easy formation on the substrate.

One last thing is that the item to print on should have a high heat resistance. It should be able to withstand temperatures up to 400⁰F without getting ruined.

Sublimation Printing on Aluminum and Other Metals

You can print a dynamic image on aluminum or other metals using sublimation printing. You should choose high-quality materials to gain best results. To get the best and beautiful effect, an efficient sublimation printer is a must. Generally, a printer with an 8-color setting is preferable.

There is one more thing to remember. Place the metal on top of transfer paper and not underneath it while printing. Ensure to properly place the images on the material without using heat tapes.

Summing up, see that the heat is touching the metal and paper directly for good results.

Sublimation Printing on Canvas

The major difference when applying sublimation printing on canvases is – you can design the canvases to be stretchable. People call this process a “Gallery Wrap”. This means that you roll the canvas print around the sides to the back of the frame. This way, your viewers won’t be able to see the tools you used in securing the canvas.

You must remember that canvas sides will still be visible and you need to print them. You can print either the continuation of the front image or a copy of the same image.

If you are using the gallery wrap style, having the canvas material larger than its frame is ideal. A larger canvas will stretch more easily.

While setting up the heat press, clean the material first with a lint roller beforehand.

Sublimation Printing on Acrylic

Though acrylic is not polyester-based, you can use a variant “Sublimation Acrylic” for sublimation printing. You can use this variant (or product) using a conventional with a conventional heat press and transfer paper without ruining it. You can get sublimation acrylic on websites or in stores that sell printing machines, materials, and other supplies.

Sublimation Printing on Wood

You can extend the sublimation printing procedure to wooden items too. It opens a new range of product options to print on. While wood doesn’t have polyester unlike several other items, you can still coat it with a poly substance by using heat and rollers.

After coating it, the rest of the sublimation printing process is similar to that on polyester items. The coating may help use the heat press at a temperature below than the standard 400⁰ for most products. You should focus on it more when applying a certain coating on the wood.

Sublimation Printing on Nylon

Nylon is one of the most challenging materials to use sublimation printing on. There are several types of nylon and each type reacts differently to the sublimation process. Among all types, Nylon 6 is the most common type businesses use for printing.

In nylon printing, you should understand this. Trying and testing to see what the best attractive result possible could be is more important. For a broad range of options, there are multiple unique results. One tip that can help would be using lower heating temperatures.

Benefits of Sublimation Printing

Coming to the benefits, sublimation printing offers a few as follows.

- Outstanding Print Quality – Sublimation printing produces vibrant, high-resolution images. As you don’t apply ink in individual dots unlike in other processes, it produces smoother color variants. It is an excellent option for both vivid and subtle colors.

- Durability – As the ink bonds chemically with the substrate, scraping or scratching off the surface is minimal. This helps attain durable and even reusable graphics.

- Ease of Use – Dye-sub graphics are lightweight and easily foldable. It makes them suitable for transportation and storage. They are washable too which makes their maintenance easier.

- Zero Glare – As graphics are glare-free, they don’t cause distraction. Hence, it is a perfect fit for fabric walls, stage graphics, backdrops, etc.

- Versatility – Sublimation printing can be useful for a variety of styles and looks. Be it graphics for trade shows or backwalls, flags, signs, tents, POS retail displays, banners – sublimation printing supports all. A popular use is Silicone Edge Graphics (SEG). In this, you print high-resolution dye sub graphics on a tension fabric. A thin silicone strip is present on the edges of the fabric. It inserts into a frame to produce amazing wide-format lightweight graphics.

Final Thoughts

Sublimation Printing is a great versatile printing process for today’s printers. Now that you know “what is sublimation printing”, its uses and methods; you are ready to start a sublimation printing business right away.

If you are looking to launch a sublimation printing business, you can get in touch with our industry experts. They can guide you about the costs and procedure to launch an e-store easily. You can also check out our web-to-print storefront solution that can help you set up your store in no time.

As I already mentioned above, the increasing demand for personalization freedom is not a fad. It is to stay here for long and evolve further. So, you shouldn’t and can’t afford to forgo it.

If you wish to provide the freedom of customization, you can check out our cutting-edge Brush Your Ideas Online Product Design Software.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Follow with us