The current custom screen printing market size in the US is $7.9bn. The market size of the screen printing industry is forecasted to increase 1.8% in 2021.

While it is true that a screen-printing business seems busy and crowded with screen-printing equipment at the moment, there are actually only a few pieces you’ll need. Equipment management and planning can surely get overwhelming. Especially, if you are a newbie you obviously will have questions like, “What do I need to start screen printing?”, “how to start screen printing?”, and more. We’re here to help!

We have put together a list of the ten most essential materials — from pre-press to printing to post-press — for your screen-printing business. With this screen-printing materials list, you’ll be able to start your screen-printing business quickly and in a hassle-free manner. So, let’s start from the beginning!

Pre-Press Equipment

Before you begin with the actual screen-printing process, there are a few things that you need to do. The pre-press process involves preparing the artwork and screens before you print them. Pre-press equipment includes things that you will need to create, format, and prepare the designs before you can start printing them.

1. Design Tool

At the very least, you’ll need a computer and design software. A computer is the most basic requirement. You need to make sure that your computer has enough computing power to run various design software and tools. Less powerful computers mean tedious workflow.

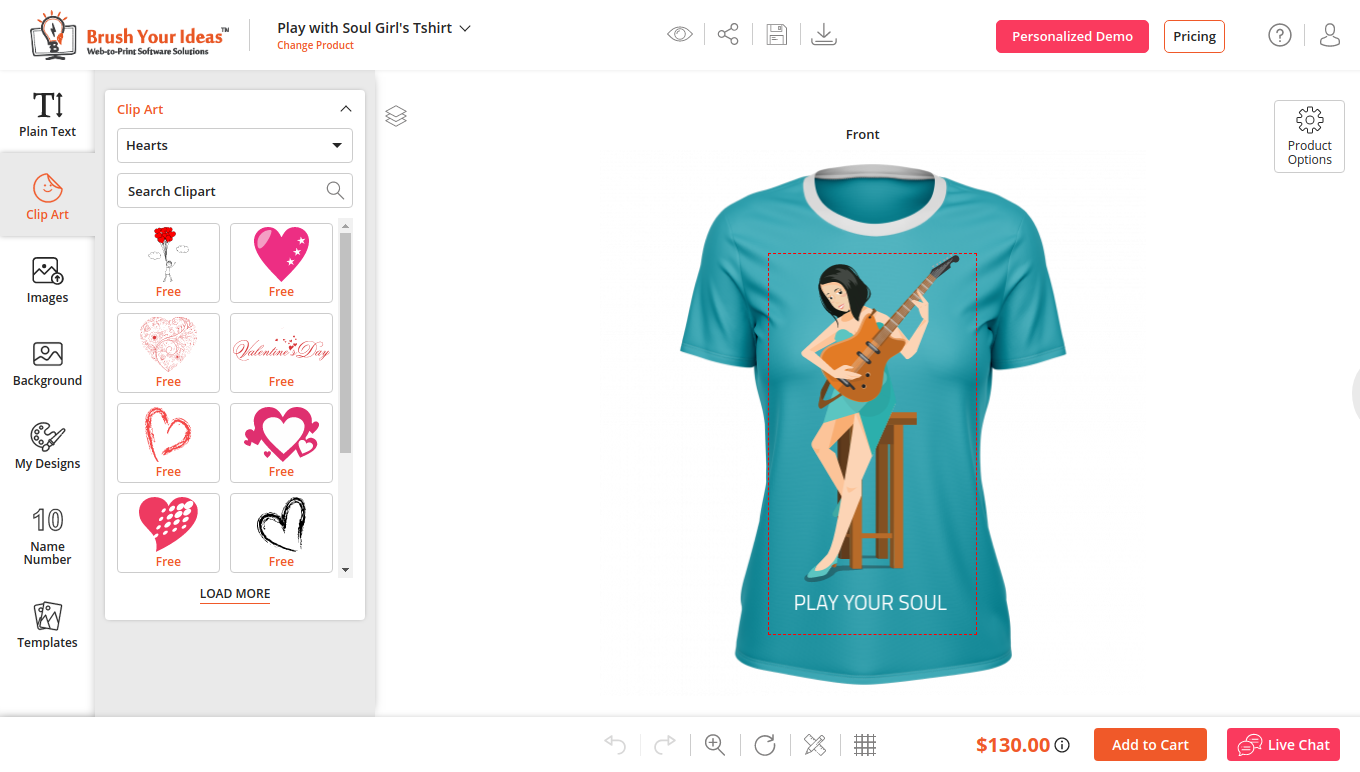

You’ll need a unique and flexible designer tool to create out-of-the-box designs that attract customers, especially if you’re offering product personalization to your customers.

You will need a flexible, intuitive web-to-print product design tool that offers everything from diverse customization features to print-ready designs. Ideally, most tools provide a massive library of images, texts, clipart, and ready templates. It must let you create personalized designs on every printable material.

You can try using Brush Your Ideas for designing purposes. It understands your business feasibility, and it is packed with diverse features that give you full control of your designs. You can even let your end-users perform customizations. Plus, it offers multiple integrations and can work with multiple platforms. Explore Brush Your Ideas Customization Software for Magento, WooCommerce, OpenCart, Shopify, PrestaShop, and more.

2. A Business Website

The next very basic requirement in the screen-printing materials list is a website. You will need to register a domain name and build your website as you want. A well-ranked website, to showcase your work to your clients can get you global attention and lots of screen-printing assignments.

With the help of this website, you can run various advertisements, be it location-based, target audience-based, and so on.

You will need a dedicated system to get and manage your consignments. If you are selling products and customized services as retail, you may need an ecommerce store or a portal to process all your orders.

Making the right choice for an ecommerce platform is more important than you think. Your ecommerce platform selection depends on your business niche. You can also select the platforms based on licensing, cost of development, customization, support services, and so on.

Some popular ecommerce platforms are Magento, Shopify, WooCommerce etc. Each platform has its pros and cons. Here’s a detailed guide that will take you through the depths of ecommerce platforms.

Consult our experts to build a website from scratch in minimum time.

3. Equipment to Prepare Stencils

Next, you’ll need to create stencils to produce a screen print. You’ll need an inkjet printer for this. It will print your designs in black ink onto a special transparent film. It lets the UV light through its clear parts during exposure and blocks UV wherever the artwork is.

- Print ScreensYou’ll definitely need screens for your screen-printing business. If you’re just starting your business you may want to stock a small supply of the most commonly used screens.

- EmulsionAn emulsion is what goes into the scoop coater. Then apply the emulsion onto the screen to make a photographic stencil. Generally, the emulsion hardens when exposed to UV light. This process is in order to create a stencil.

- Scoop CoaterTo spread the emulsion evenly, you’re going to need a scoop coater. The next step would be to take it over to the exposure unit.

- Drying RacksScreen drying racks are important. You will need them to lay screens on for the emulsion to dry.

4. Exposure Unit

After the emulsion coating process, the screens are kept in a special UV exposure unit, with an LED vacuum on top. This photographic process is to cure the stencils. You will need a light source, particularly a UV light source. The Sun is a great source of UV light, but you cannot rely on it as it is not going to be nice and sunny every time you print.

It is very important to select the correct light source for more efficiency. Some of the most popular light sources according to industry standards are blue fluorescent tubes, quartz lights, etc.

5. Washout Station/ Pressure Washer

You’ll need a washout station and a water source to wash the stencils out of the screen after exposure and also to reclaim the screens after the press runs. During the reclaiming process, you need to be careful and try not to spray water over the printed area.

You can go for either a regular garden hose or a pressure washer as a water source in your washout station. The purpose of a pressure washer is for various screen-making processes such as stripping the screen of emulsion, de-hazing, mask wrapping, and so on.

Last but not the least, you may also need things like Scrubbing Pads, Washout Brushes, Paper towels, Protective goggles, and Gloves for your wash station unit.

Screen Printing Equipment

Now, let us look at the screen-printing equipment you’ll need for laying down your prints.

1. Screen Printing Ink

You can choose any type of ink from plastisol, water-based, and discharge inks. If you’re just starting your business, you may want to try different brands and figure out what’s best for you. You can start with a basic ink mixing pack, with some regular, local-school colors. You may also need plastic containers and ink scoops to help you handle your ink. Most screen printers also use scales and mixers to help you prepare the inks.

2. Screen Printing Press

Choosing a press is a personal decision which should be made thoughtfully. Your ultimate success will depend on the flexibility, usability, and capability of the printing press.

-

- Decide the SubstrateBefore you think about choosing the type of print machine, you need to know what all substrates will you print on. So, decide the substrates beforehand. It could be any printable material such as t-shirts, bags, banners, signage, or other items.

- Choose a Press

Once you’ve chosen your substrate, choosing a press won’t be difficult. If your budget is low, try not to fall for the cheapest machinery available. Balance the cost-effectiveness and usability of the printing press. Choose an entry-level printing machine that also offers an upgrade path, flexibility, and can print multi-color jobs without wasting time and raw material.

3. Squeegees

The next important thing in the screen-printing materials list is a Squeegee. After you expose the screen under the exposure unit to create a stencil, you will need a squeegee to press on the substrate.

Squeegees pull the ink across the screen and are responsible to lay down the print. There are different types of squeegees available in the market. You may want to stock a few basics to see you through your usual print jobs.

4. Flash Care Unit

The purpose of flash care is to flash dry between print colors. It allows you to cure your inks partially so that you can print white underbase with overlapping colors.

For example, if used for a dark background, it is difficult to ensure that the top ink layer is highly opaque or not. In such a scenario, the flash care unit has no job. The Flash care unit is essential equipment and a screen-printing entrepreneur cannot afford to be without it. It is a valued piece of equipment on most screen-printing floors.

Post-Press Equipment

There’s only one necessary piece of pre-press equipment: The conveyor dryer. You’ll need conveyor dryers to heat your ink up to the curing temperature in order to ensure that the prints last. It gives your printed product a hard-wearing and high-quality professional finish.

You may want to invest in heat sensors: a heat gun or a heat tape. They’re generally used to ensure that the ink reaches the required curing temperature when it comes out of the dryer.

Other Essential Equipment

You may also need the following things for your screen printing processes:

-

-

- Ink DegraderInk degrader is a water-soluble cleaner for the removal of inks before reclaiming the screen. It effectively degrades a variety of inks without attacking the emulsion. The choice of the ink degrader will depend on the type of ink you choose. If you have chosen plastisol ink, you’ll need an ink degrader that is optimally applicable for plastisol inks.

- Stencil Remover (Emulsion Remover)You’ll need stencil remover to reclaim the screen. You need to clean the ink on the screen before you apply any emulsion remover. You will need to rinse it with high pressure after you apply it for a couple of minutes.

- Spray Tack/ Spray AdhesiveYou’ll need a spray tack if you’re printing on substrate-like t-shirts. Spray adhesive is applied to the palette so that the substrate stays put and doesn’t move while you are printing it.

- Mesh PrepMesh Prep is a water-based preparation generally used for the removal of grease. It is a wetting agent for stencils on the screen-printing mesh. It also improves the coating quality and emulsions.

- Haze RemoverUse haze remover to remove most ghost images and stubborn screen stains. Choose the one that is a mixture of strong caustic and powerful solvent. They’re highly effective against screen stains and can make the screen like new again within the period of ten minutes.

- Packaging MaterialLast but not least, do not forget to get the packaging material for delivery. You’ll need boxes and postage for sending out your printed products to your paying customers!

-

Conclusion

Hence, the screen-printing materials list comes to an end. We have covered all the basic screen-printing equipment requirements. We hope we were able to answer all your questions pertaining to “what do I need to start screen printing?”, “What kind of equipment to look for?”, and “how to successfully begin your screen-printing business”.

While researching the screen-printing business, it can leave you feeling like you’ve traveled down a rabbit hole. But there is relatively very little you need to do to start your own screen-printing business. Essentially, if you invest in all the right equipment, have the perfect product design tool, and have a well-run and updated website, you’re good to go! We hope that with a few quality basics, you will be churning out your own screen-printed products in no time.

For any other questions related to screen printing equipment, screen printing business, a product design tool for your business, website development, and so on, you can directly contact our experts. Our product comes with the top functionalities that will help you acquire, engage, and serve your potential customers in the best way possible. We guarantee that our team of expert developers will get you through every difficulty as you embark on this journey ahead.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.

Follow with us